Warranty and after-sales service conditions

30 For everything

30 For everything

What does vindors warranty protect you from?

- After some time, your client reports that the window panes are leaky.

- Your client’s windows fogged up from the inside.

- After two years, the handle broke during use.

- The weld in the uPVC profile broke after a long time after installation.

- After a year, the paint on the aluminum profile began to peel off.

YES, 30/42 months of the Worldwide debesto Warranty protects you from all of these issues!

Conditions of Worldwide debesto Warranty

I. Formal:

Guarantor: Vindors (independent of the manufacturer’s warranty conditions)

Warranty Options (effective from the date of goods production):

- 30 months – standard warranty

- 42 months – extended warranty for an additional 3% of the goods’ value for the extra year

Area of Application: Worldwide

II. Practical:

1. Checking the goods during transport:

Be sure to inspect the goods in the presence of the delivery driver and write down any damage found on the CMR document in pos. 24, and take photos of the damaged goods

- Remember – before signing the CMR, take as much time as you need to verify the delivered order. The driver is obliged to wait until you carry out the checking process after unloading

- In the case of personal collection – if some elements of the order or goods are missing or damaged, be sure to take photos and write a statement in the presence of the warehouse employee

- Remember to send the complaint form in accordance with the procedure in point IV of this guarantee

- You have 7 days from the delivery / receipt of the order to report any visible physical defects and missing elements

2. Checking the goods before installation:

- The Buyer is obliged to check the quality and the mechanics of the product prior to installation and during assembly prior to permanent fixing of the product in the construction of the building (in particular before using mounting foams, mortars, sealants, etc.), which leave permanent marks on the product structure

- If the defects could be found before mounting the product, the Buyer loses the right to warranty claims with the beginning of the installation

- Any interference in the goods or any changes to the goods, both permanent and temporary (such as, among others: trimming elements, painting the surface) result in the loss of warranty

- If the goods are ordered to replace other dismantled windows and doors, the Buyer is obliged to check the operation of the purchased products before disassembling the earlier structures. In the event of a malfunction, it may be necessary to return the defective products. Disassembly of previously installed products does not entitle the Buyer to any claims against debesto. Remember, if you do not check the delivered goods in advance for condition and compliance of dimensions, you disassemble at your own risk

- In relation to Buyers other than consumers, the warranty for defects in goods (PL: rękojmia) is excluded

3. Self assembly:

- Installing the products on your own is acceptable, but the windows and doors must be installed in accordance with the guidelines of vindors. In cases not specified by vindors, the general rules of construction practice apply

- Any defects or malfunctions of the goods caused by lack of maintenance, improper installation, improper maintenance or improper use as well as any mechanical defects and failures are not covered by the warranty, and the Buyer is responsible for their removal.

III. Assembly requirements:

- Installing the products on your own is acceptable, but the windows and doors must be installed in accordance with the general rules of construction practice.

- Here are examples of installation requirements, which will eventually decide about correctness or incorrectness of the installation:

Water resistance

Construction- matter solutions of the building envelopes and their weatherstripping should prevent the infiltration of rainwater into the building.

Thermal permeability and dew point

There mustn’t be any condensation of the steam on the inside surface of the non-transparent building envelope as this may enable the development of the mould. In order to keep this solution, the building envelope and their structural joint should be marked by temperature coefficient fRsi of an amount not less in value than critical value. Presuming the required value of this factor equal to 0,72 is also allowed.fRsi is the difference between inside surface and the temperature of the outside air, divided by the difference between the temperature of inside and outside air.

Air permeability

In the building, the connection of windows with the jamb should be designed and done in respect of the achievement of their full airtightness. The correct assembly of the window and balcony door in each case should guarantee at least fulfilling of the technical and construction requirements. If it is known in advance that the requirements will not be fulfilled, then performed service should not be called as the “assembly of windows”.

Mechanical connection of the window with the jamb

Taking into account the values of loads affecting the installed windows and the inevitability and repeatability of phenomena causing wind loads, four rules can be defined to be followed when performing the “mechanical” part of window and balcony door installation:

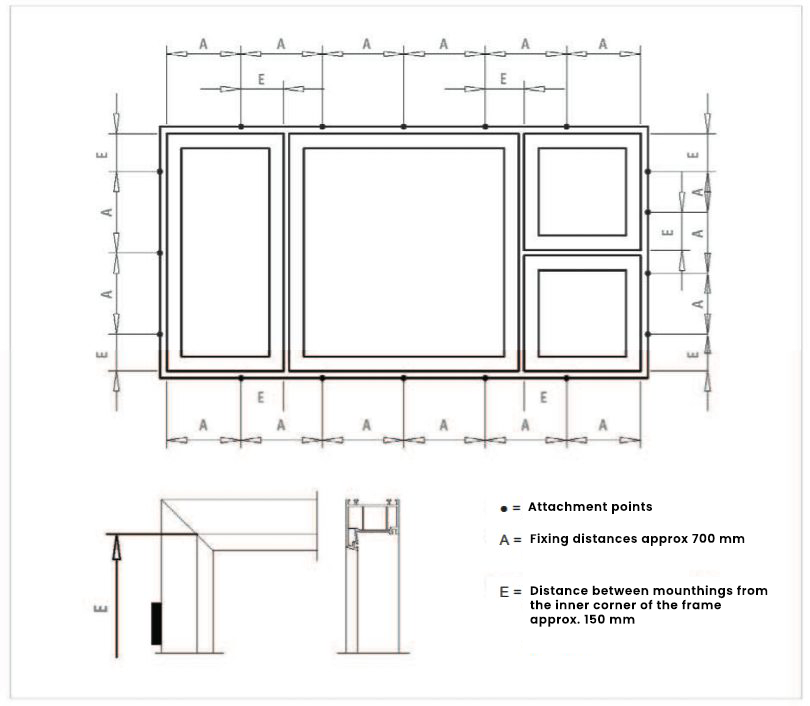

- Window constructions must be mechanically attached to the frame.

- Due to the values of the forces acting on the window structure, which are a derivative of wind velocity pressure, in the case of windows and balcony doors installed in facade openings, it is generally necessary to provide four-sided mechanical fastening of each element using appropriate assembly means, observing the application recommendations issued by the manufacturer.

- In the case of boxes for top-mounted shutters, the upper rim of the frame, which cannot be mechanically fixed, should be statically calculated as a free-bearing element and properly fixed on the sides.

- According to the current state of technical knowledge, it is not allowed to fix windows in the reveals only with polyurethane foam, glue and similar building materials.

“Arrangement of the fastening points for windows made from plastic should be as presented in the picture”. (Aluplast, Assembly Handbook).”

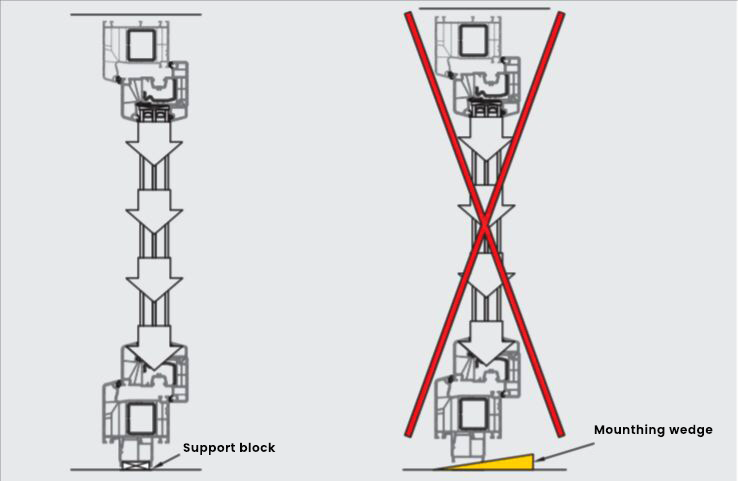

Proper use of the support blocks

Transferring wind loads from the window to the building wall is possible only if we ensure during assembly that the mechanical fastening points will not be affected by additional loads resulting from the weight of the structure.

Support blocks (Picture 1) are the element responsible for transferring loads from forces acting in the plane of the window to the wall of the building.

The support blocks do not have to be permanently attached to the window or building structure. They are an element loaded “on pressure”.

Warning! All of the patio windows/doors demand the arrangement of load-bearing elements under the threshold every min. 11.81 in, provided that they shall not project above the threshold. This will prevent the movement of load-bearing elements by accident.

Common assembly mistake:

When starting the support, it is worth remembering that wooden assembly wedges (Picture 1, right side), most often used to fix the window position in the jambs and placed perpendicular to its plane, are not supporting

Wedges, which serve as auxiliary fastening elements during assembly, should be removed after the window has been installed, and the place left by the wedges must be supplemented with a thermal insulation layer.

Requirements have been developed based on the “Window vademecum uPVC 2018”, ALUPLAST.

Picture 1 – Wedges, which serve as auxiliary fastening elements during assembly, should be removed after the window has been installed, and the place left by the wedges must be supplemented with a thermal insulation layer.

Supporting materialsThe general principles of building art can be found below:

1.Detailed instructions of assembly windows can be found in Assembly Handbook- Aluplast.

2. In cases not specified by vindorsb2b.com, the general rules of construction practice apply.

3. Irregularities in the action of windows and doors related to incorrectness of its setting, maintenance or exploitation are not a subject of a warranty and should be handled by the buyer.

IV. Application procedure:

1. All complaints have to be submitted in electronic form only through properly and completely filled out form located at vindorsb2b.

2. When sending a complaint, the Buyer is obliged to:

a) Indicate the number of the proforma to which the application relates

b) Indicate the position numbers of all items on the specification that are the subject of the complaint, along with the number of goods (e.g. pos. 005 – 2 pieces)

c) Accurately describe the defects or missing elements,

d) Provide photographic or video documentation of the goods.

Minimum technical requirements for attached multimedia materials:

– Photos and videos should be taken in daylight, or if this is not possible, use artificial light to record a detailed and not blurred picture

– The minimum required resolution of the photos is 8 megapixels

– The minimum required video resolution is 1920 × 1080 (Full HD) at 30 frames per second.

3. If the submitted documentation does not allow for an unequivocal assessment of the legitimacy of the complaint, we will request you to complete the documentation, thus extending the time to process the application.

4. Complaints are handled electronically, with the possibility of phone communication.

5. Time for examining the complaint: 14 days from the date of submitting the complete application documentation, unless the examination of the complaint requires special measures or information – in this case, within 14 days from the date of submitting the complete application, vindorsb2b will indicate a different technically and technologically possible deadline for considering the complaint.

6. Vindors has no mobile service technicians and all matters are resolved with remote cooperation of both parties. Vindors points out that the goods offered are specialist goods and their assembly should be performed by people with appropriate knowledge, qualifications and experience in this field. The Buyer performs the installation on his own, at his own cost and risk.

7. If the complaint is accepted:

– The repair or replacement of the defective goods will take place within the prescribed time limit, possible for technological, logistic and production reasons

– The cost of possible transport of the goods is covered by vindors.

As part of the removal of defects in goods, it is possible to release only parts, components or structures of the goods. Any work related to the removal of defects is carried out at the expense and sole risk of the Buyer.

8. Alternatively, the Buyer has the right to submit a claim via the European Online Dispute Resolution platform.